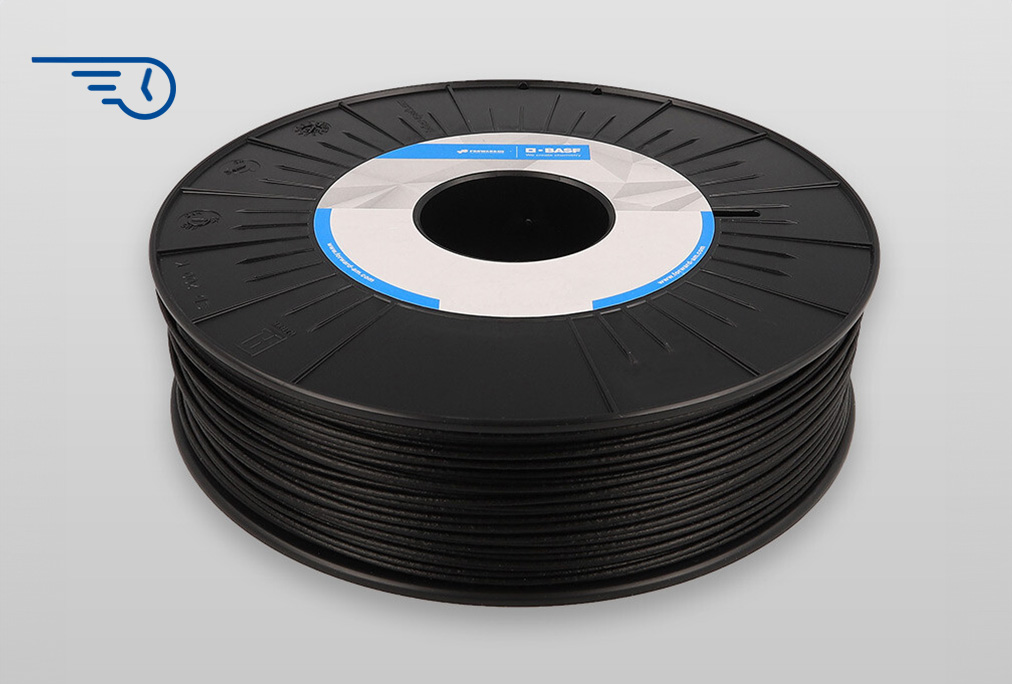

filaments

Ultrafuse® PC GF30

Ultrafuse® PC GF30 is a unique compound of PC with 30% glass fibers, specially designed for FFF printing.

With its high heat deflection temperature and good dimensional stability, Ultrafuse® PC GF30 is the right

material to use in an industrial environment where good temperature resistance and high strength is needed.

Its UL94 V0 rating makes PC GF30 the perfect solution for applications in transportation industry that require

flame retardancy. The resistance to UV light exposure and its low moisture uptake makes Ultrafuse® PC GF30 highly

suitable for interior and exterior applications.