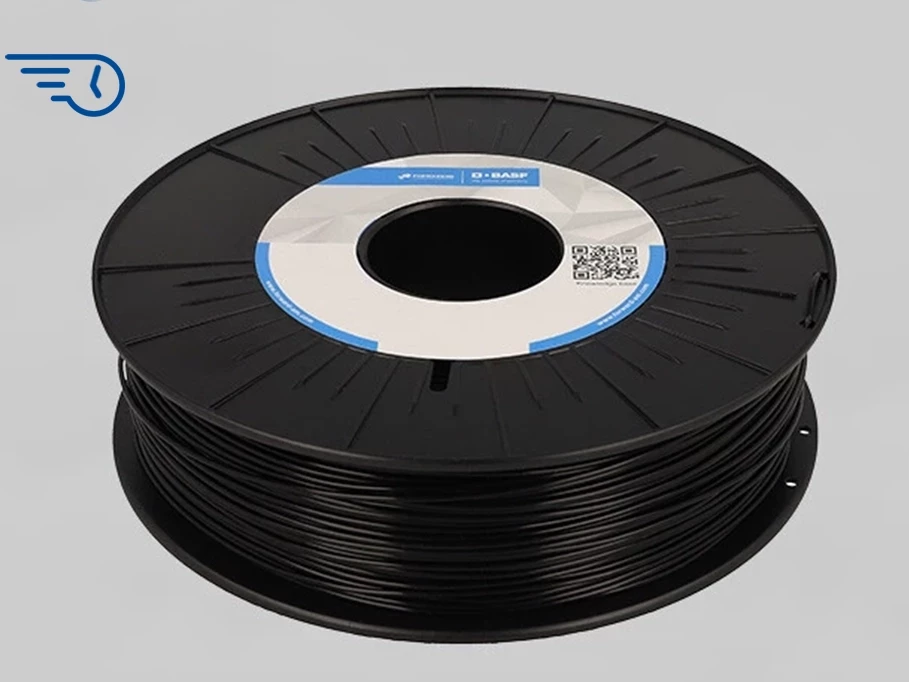

filaments

Ultrafuse® PLA Tough

Ultrafuse® PLA Tough is a highly versatile biocompatible and biobased material specially developed for the needs of professional users. It effortlessly accommodates validated high printing speeds up to 300mm/s1, without the need for any hardware adjustment while offering an exceptional surface finish and an impressive impact strength. Moreover, it boasts a notably high success rate for large print jobs, ensuring a straightforward and cost-effective printing process.

Ultrafuse® PLA Tough can be an alternative to ABS as it is more sustainable, strong, and easy to print. As it is compatible with water-soluble BVOH support material, this biocompatible material which exhibits an impressive impact strength – 720% higher than standard PLA – is the perfect solution for printing complex geometries for demanding high-volume applications.

Furthermore, Ultrafuse® PLA Tough parts can be enhanced by annealing the part in a separate process step, which can increase the toughness up to 230% and its heat resistance by 257%.

With Ultrafuse® PLA Tough Filament, you can achieve sustainable, cost- and time-saving production of large components at rapid speeds while maintaining impeccable surface quality. Elevate your designs and projects to PRO levels with a filament that guarantees outstanding performance, reliability, and consistency.